Sipping on a crisp and delicious beer is something that millions of people around the world enjoy doing every day. Beer has been a staple drink of many cultures for thousands of years, and its popularity is high. However, traditional beer is not gluten-free. As more and more people find out about their affliction with celiac disease or a gluten intolerance or sensitivity, there is more and more demand for gluten free beer.

In this article, we’ll cover the relationship between gluten and beer. We’ll go over exactly how traditional beer is made and how gluten free beer is made. We’ll also provide a gluten free beer list and some of the ways you can find “gluten free beer near me” in your online search. After finishing this article, you’ll know how to find the best gluten free beer out there! Let’s dive in.

Traditionally, yes. Beer is typically made of just four ingredients, but sometimes other ingredients are added for flavor. The main four ingredients are barley, hops, yeast, and water. Gluten free beer is not only totally possible to create, but is increasingly widespread and safe for consumption by both those with celiac disease and gluten sensitivities. To best understand how gluten free beer can be made possible, we should first cover how traditional beer is made.

Keep in mind that gluten is found in all forms of wheat, barley, rye, and most types of oats. These grains are the only source of gluten during the production of beer. Hops and yeast have no traces of gluten as long as they are processed in certified gluten free facilities.

Beer begins with the malting process. Raw grain (either barley, wheat, rye, or oats) is germinated in a controlled environment. After germination, the grain is then dried using hot dry air or even sometimes roasted to impart some flavor. This is most commonly done at a separate facility from the brewery. Once the grain is transported to the brewery, it is then milled to remove any hull. This will bring out the starches, which can either be used in the flavor of the beer or rinsed away to make a more mild flavor.

The next steps are part of the mashing process. The malted and milled grain, known as the grist, is combined with water in a steel tin and heated to between 100 and 170 degrees Fahrenheit (37 to 77 degrees Celsius), typically using steam. This reaction causes enzymes in the grain to break down the starches. This process imparts the largest amount of flavor and takes under two hours at a consistent temperature.

After the mashing process is finished, the liquid (wort) and solid (spent grain) components are separated. This process is called lautering. The first step of lautering is to reheat the beer by bringing it to 170 F (77 C). The liquid is recirculated through the solids once or twice to ensure that the finest particles are filtered out. Then the liquid wort is finally separated from the solid spent grain. Hot water is rinsed over the spent grain to ensure that every flavor source has been extracted. This grain is then typically used for livestock feed.

The liquid wort is then boiled to ensure pasteurization happens. This kills the active bacteria and ends the first fermentation process. As the wort is pasteurized, hops are added at a specific time during the boil to determine the specific flavor of the beer. If the hops are added earlier, for instance, then the beer will be more bitter. The hop proteins and solids are then removed from the liquid.

The second fermentation process begins by cooling the liquid to the desired fermentation temperature. Then, yeast is added to kickstart the primary fermentation of the beer. A different yeast will produce a different flavor, and the change in fermentation temperature will produce a different kind of beer. Of course, the longer a beer is fermented during this stage, the flavor and type of beer will change.

The primary processes of making beer have now been completed. The next phase is then known as conditioning, which can either be a period of the beer resting or a third round of fermentation. Conditioning takes anywhere from one to six weeks as the brewers reach the exact quality of the beer they’re going for. After the intended flavor has been reached, the beer will be bottled and carbonated for preservation. It will finally be ready to drink!

As you know by now, only two certainties can render a beer gluten-free. Most importantly: the type of grain used in producing beer must not be a variety that contains gluten, including barley, wheat, rye, or oats. Also of paramount importance is whether or not the grain was processed in certified gluten free facilities, avoiding any possibility of contamination during harvesting, processing, malting, and transportation.

There are actually two ways of producing a gluten free beer:

The first way is to use an entirely gluten free grain during the malting process, such as rice, corn, sorghum, quinoa, or millet.

The second way is to use glutenous grains (barley, wheat, rye, or oats) and reduce the gluten during the first fermentation. This is done by introducing an enzyme, such as Brewers Clarex, during the fermentation of the wort, which will break apart the gluten protein. Gluten is then filtered out with the remaining spent grain solids.'

There are several conditions for a beer to be considered gluten free. Without both of these conditions, no gluten free beer can be guaranteed entirely gluten free. Here is how you can be sure that your beer has zero gluten whatsoever:

The beer needs to be produced entirely using gluten free grains such as buckwheat, corn, rice, millet, sorghum, quinoa, and more.

From start to finish, the beer and all its ingredients need to be handled in an entirely gluten free facility. This means that the grains need to be harvested and processed using equipment and a facility that doesn’t process wheat. Then, they need to be fermented and brewed in a similarly entirely gluten free facility. Finally, the beer needs to be bottled using equipment that only uses gluten free beer.

The only way to be sure about all this is by buying from breweries that are dedicated to their gluten free customers by applying to both of these conditions. What makes this much easier is that these dedicated gluten free breweries are proud to say so. It will definitely be proudly displayed on both the website and the product itself.

Holidaily Brewing Company, located in Golden, Colorado, is a brewing facility that is certified entirely gluten free. This means that gluten never once enters the facility and everything is packaged in house. Their delicious Beulah Red Ale provides a level of flavor that those with celiac disease and gluten sensitivities rarely get to enjoy. Be sure to check out any one of their incredible gluten free beers from an outstanding lineup!

Researchers have found and developed various enzymes which actively break down the gluten protein into much smaller molecules. This enables the body to process the molecules as part of normal digestion. It is important to know that while these enzymes do a great job of removing harmful gluten from beer and other food products, they are not bulletproof solutions for completely eliminating gluten from a diet. What these enzymes can ensure with proper use, however, is that a product can be certified gluten free with a gluten count of less than 20 parts per million (ppm).

One of the most trusted gluten reducing brewers’ enzymes on the market is Brewers Clarex, sold by DSM Food and Beverage. Brewers Clarex is well known and effective at assisting in the production of gluten reduced gluten free beers around the world. Here is how the enzyme does its job:

It eliminates colloidal haze.

Filtering is an essential process in producing many of the world’s beers. Many beer varieties are left unfiltered for flavor reasons, which makes the beer look cloudy. These microscopic particles, known as colloidal haze, are indeed parts of the glutenous grains which were fermented. In order for a beer to be certified gluten free, this colloidal haze must be removed. However, this is quite difficult to do and most brewers want to avoid the process altogether.

Brewers Clarex stabilizes the grain during initial fermentation so as to avoid the excess breakdown and ejection of starches and particles. This works well to avoid the often necessary cooling phase before the grist is combined with water.

It degrades the gluten molecule.

An antigen is a molecule that binds to antibodies or T-cell receptors in the body. The presence of antigens will begin an immune response, which leads to inflammation in those with a certain allergy.

An epitope is a specific piece of the antigen with which it can bind with antibodies or T-cell receptors. Without the epitope, it’s not possible for antigens to provoke an immune response in the body and the molecules will be flushed out with waste.

The Brewers Clarex enzyme specifically targets the epitope of the gluten antigen, destroying its ability to bind with antibodies and T-cell receptors. This prevents gluten molecules from provoking an immune response in the body, rendering them harmless.

After Brewers Clarex has been applied to a beer during the first fermentation phase, gluten molecules will be rendered essentially useless. It will also make the filtering process much more simple for brewers. By degrading the gluten molecule and eliminating colloidal haze, Brewers Clarex will make any glutenous grain based beer safe to drink for those with celiac disease or gluten sensitivities.

As anyone with celiac disease knows, the best selling brands of beer around the world are by and large not suitable for those on a gluten free diet. None of the top ten best selling brands of beer can be considered gluten free. Even though gluten free beer is not yet available in every restaurant or store, it is growing quickly in demand. Today, many microbreweries are starting to feature gluten-free beer.

In order for a gluten free beer to be approved according to legal standards, the beer will be tested sometime during the various processes but no later than during the conditioning phase. The beer will need to be confirmed at lower than 20 ppm of gluten in order to be considered a gluten free beer. This benchmark is considered safe for those with celiac disease and gluten sensitivities to consume a product.

Depending on the level of your gluten sensitivity, you may have different experiences than others when it comes to gluten free beers. Those beers that are entirely gluten free throughout the process are a much safer bet for those with celiac disease. Those beers that are gluten reduced may still trigger a reaction in those with an intolerance to gluten.

You may have heard that certain beers in mass production actually have a low gluten content because they add corn or rice as part of the grain mixture. These beers should not be considered safe to drink for those with celiac disease or a gluten sensitivity. Unless a beer has been proven or tested gluten free, it should be avoided for those with the affliction.

Gluten free beers can be organized into three main categories:

Proven Gluten Free: These beers are produced in facilities that never use gluten whatsoever, ensuring that the product is never contaminated.

Tested Gluten Free: These beers are produced in facilities that may use gluten, but never in the production of this product. It is possible that sometime during the production of the beer that it was contaminated with gluten. However, it has been tested to be below the required 20 ppm and approved.

Gluten Reduced: These beers are produced with glutenous grains. During the process, they are treated with an enzyme that breaks apart the gluten protein, which is then filtered out. The product is then tested to be below under the required 20ppm and approved.

Many major beer manufacturers have indeed made moves to offer a safe and delicious gluten free beer. Let’s look at a few of the best and highest selling gluten free options from major beer distributors.

Redbridge Gluten-Free Lager: Made by beverage giant Anheuser Busch, this beer has become a favorite in gluten free communities across the United States and beyond. The grains used are sorghum and corn. While no gluten is used during production, Redbridge is produced in a facility that uses gluten. During testing, however, it is approved gluten free for those with celiac disease and gluten sensitivities.

Shrouded Summit White Ale: While drinking this amazing beer, you’ll be transported into a Belgian pub. Ghostfish Brewing Company is responsible for creating such a delicious beer and it is certified gluten free. The grains used are millet, buckwheat, and rice. The flavorful yeasts included in the brew give the impression of a classic Belgian witbier (wheat beer) without the struggle for those with celiac disease.

Omission Lager: Omission is a major brewery located in Oregon and their lager has been adapted by many with gluten sensitivities. Omission brews all their beers with glutenous grains and uses an enzyme to reduce gluten in their beers. Their Lager is tested to be gluten free, but they cannot give a guarantee that the beer does not contain any particles of gluten.

Sticks Pale Ale: Bootstrap Brewery makes this delicious pale ale that is just as complex as it is drinkable. Even though it’s made with barley, Sticks Pale Ale is a beer that has been proven to be gluten free through enzyme reduction and testing. As always, any of those with celiac disease should be careful. If at all possible however, know that this is a great beer that should be enjoyed.

Space Cadet Cream Ale: Gravity Brewing has made a beer that is best enjoyed on a relaxing porch swing in the summer. The light flavors of this cream beer include vanilla and make for a very drinkable and fun beverage. Space Cadet Cream Ale is also gluten reduced through enzyme reduction since its primary grains are barley and wheat. This is a beer you can really learn to love!

The IPA, known in long form as the India Pale Ale, is a type of beer that falls within the larger pale ale category of beers. The main characteristic of the IPA is the complex and bitter flavor that is provided by a larger amount of hops and a longer steeping time with the wort. This is the biggest difference between IPAs and the broader categories of traditional beer, which are much milder in taste. Not everyone loves the bitterness of an IPA, but it remains one of the most popular types of craft beer around the world.

Apart from its deeper focus on flavor from hops, the IPA is just like any other type of glutenous grain based beer. When made from barley, wheat, rye, or oats, It can come in its full glutenous form as well as a gluten reduced form with the addition of enzymes such as Brewers Clarex. When made from a non-glutenous grain source, the same process of focusing on hops will make a delicious gluten free IPA.

A wonderful gluten free IPA is the Stone Delicious IPA. Stone Brewing has carved out a spot for themselves in the major beer market of the world though they still retain their craft brewing principles. The Delicious IPA is made gluten free by the enzyme known as Brewers Clarex, which reduces gluten from its natural sources. Delicious IPA is a fantastic craft beer that has been tested to be gluten free.

A popular variation in the India Pale Ale category is known as the Hazy IPA. By and large, this type of beer is so much like every other kind of IPA and gluten free beers, but it’s this unique and amazing combination in the middle that makes it so popular. Let’s go over the allure of the delicious Hazy IPA variety and how it can be classified gluten free.

Your first impression of any draft beer is a visual one. A Hazy IPA is known for its cloudy appearance. You can see through a pilsner, for example, but you can’t see through most Hazy IPAs. Beyond its appearance, Hazy IPAs are less bitter, and often with a fruity or “juicy” palate. The beer itself isn’t brewed with fruit. The hops do all the work!

Now, let’s discuss whether you can enjoy a Hazy IPA that is gluten free.

To recap, the two ways that an IPA can be considered gluten free are either by using completely gluten free grains or by reducing gluten using enzymes during fermentation. The majority of gluten free IPAs are made gluten free using the enzyme technique and it has turned out some impressive results.

The original purpose of applying enzymes such as Brewers Clarex to a beer is to eliminate the so called colloidal haze which gives the Hazy IPA variety its name. Since the majority of gluten free IPAs use the enzyme technique to reduce gluten, the unfortunate side effect is that all the colloidal haze is removed from the beer. This means that a Hazy IPA needs to be made from gluten free grains from the start in order to retain the intended flavors. As a result, fully gluten free Hazy IPAs are somewhat hard to find.

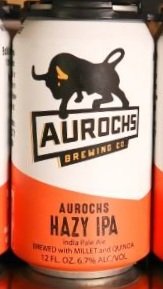

An excellent gluten free Hazy IPA is the Gluten Free Hazy IPA from Aurochs Brewing Company. It retains its flavor of the delicious haze through avoiding enzyme enabled gluten reduction. This is because Aurochs Brewing Company uses entirely gluten free grains from the beginning, namely millet, quinoa, and buckwheat. With a stunning flavor profile and that strong hoppy taste that IPA drinkers love, this beer shouldn’t be passed over.

One of the most famous beers around the world is the lager from Stella Artois and so many people around the world have grown to love the taste. As a major brewery, Stella Artois has also produced a gluten free variety of their famous beer. Stella Artois Gluten Free uses the same time-honored ingredients as its older sibling, which allows it to have the same exact taste. It goes through the enzyme introduced gluten reduction technique that ensures a gluten count of less than 20 ppm. This means that Stella Artois Gluten Free is safe to drink for those with celiac disease and gluten sensitivities.

For those looking for a similar flavor as Stella Artois, Peroni also makes a delicious gluten free beer: the Peroni Nastro Azzurro Gluten Free. It’s gluten reduced and a wonderful option for those looking for a classic taste that works well with a restricted gluten free diet.